Products

Commercial and Industrial Tanks

Cylindrical

We specialise in commercial and industrial tanks engineered and designed for modular, on-site bolted construction.

At times, off-the -shelf engineering and products are available for economy and rapid deployment here and overseas. Off-the-shelf and Custom Designs and Specifications both utilise sectional, modular plates or sheets mostly in steel.

Capacities – to 40ML (40,000m3) based on configurations of diameter from 4 meters to 116 meters, with heights ranging to beyond 40 meters.

Suitable – for a wide spectrum of water, liquids and some fuels (API codes available). Tank are protected with various coatings or flexible membrane linings for longevity and lower maintenance.

Coatings – Glass Fused Tanks to Steel and Epoxy, modified system – both are “factory coated” and furnace fused or oven baked within meaning of ANSI–AWWA Design Code D103-97

Galvanised or Painted – (wet sprayed or powder coated) in a wide range of colours.

Roof Covers – optional selection of roofs, including designs of low-level Deck style, Dome of the geodesic type “Geodome”TM, low profile Dome elevations and Bio-Gas/Anaerobic Digestion Membrane Cover Roofs.

Materials of Construction – for tanks – Aluminium, Stainless & High Tensile Steel

Codes & Standards – Tank are manufactured in Australia and overseas so we can offer experience and compliance to a range of ASA – Australian AS or ANZS standards and global standards & codes. Such as ANSI – AWWA, ASCE, API, BS and EN

Often buyers seek commercial and industrial tanks complying with one or more of these codes. We also offer proprietary, in-house design codes usually in combination with one or more of the above.

Specifiers and Owner’s regularly seek conformance with, typically AS 1170 and parts there-of. Or ANZS but tanks can not be designed in isolation to either without reference to more tank-specific design formulae. Our collective team can make that happen for stakeholders.

Rectangular Tanks

Sectional, bolted together modules for the wall and floor in these tanks and are available in a range of materials, finishes and sizes. Typically for Potable Water, Cooling and Fire Service applications.

The square or rectangle configuration is not as cost effective as the cylindrical, however they suit installations in and on buildings, especially for Fire Service storage.

Some of our Commercial and Industrial Tanks

Civils

Construction

Tank Capacity Charts

Municipal Tanks

We have a long standing history of supplying Municipal tanks for town water storage or recycling, treatment of water and sludge processing as the demand for larger, taller and “high-end” quality tankage has continued to grow.

High-end quality storage tanks match the longer Design & Service Life sought for these assets which are now incorporated into Asset Registers by Water Authorities and Municipal Town Councils. This controlled flight to enhanced quality and lower maintenance water tanks has better suited the product and services we offer at pmt Water Engineering. Especially the bolted on-site tanks with factory applied coatings. Typically to ANSI–AWWA D103 design code.

We specialise in prefabricated tanks, (both atmospheric and pressurised) mostly in steel, coated with various factory coatings. These are bolted on-site for a complete installation including “turn-key” either in existing so called Brown or new Greenfield sites.

We provide tanks for water, potable water, sewage, recycling & re-use water, sludge and biological processes such as digestion, including methane & ethanol production. Our bio-digestion system tanks for waste recycling and energy production utilise proven European engineering and technology.

Our Municipal and town water tanks and digester processing tanks have been supplied and/or installed by pmt Water Engineering from:

Perth to the Philippines and Papua New Guinea, Qatar to Queensland and also, Kingaroy in Queensland to Kihi Kihi, in New Zealand.

SEAWATER, RO & DESALINATION AND DRINKING WATER

There is an increasing use of membrane filtration & treatment, typically Reverse Osmosis “(RO)” to achieve desalination water from the sea or brackish water. This increase for both potable drinking water and industrial or irrigation use, has created demand for:

Tanks with exceptional coatings and protection to resist corrosive seawater and RO membrane permeate water. Demineralised water and these desalination waters are often described as “hungry”. They have been stripped of various salts etc and they now tend to become more corrosive and thus hungry to redress the chemical imbalance present in these treated waters.

We offer a range of materials, coatings and linings to help combat this corrosive hunger.

DESIGN REQUIREMENTS & SPECIFICATIONS

Locations of these Tanks & Digesters invariably encounter Siesmic-earthquake conditions. Especially in Papua New Guinea and New Zealand. Elsewhere, high winds or Cyclones & Hurricanes present challenges in the design of the tank/s and foundation civils. Particularly, the tall narrow “Standpipe” storage tanks we are asked to build.

Flat terrains & topography common in Australia and the Middle East also need careful consideration at the design stage. All these loads and conditions and remote or coastal locations are routine design & execution challenges for pmt Water Engineering and the collective teams we represent.

We provide solutions, on sand or in the snow for liquid management and storage.

Rural Tanks

We are proud to introduce our range of PACIFIC MODULAR WATER TANKS designed specially for diverse Australian conditions and beyond. There is a Pacific Modular Tank for your every need, from home & horticulture to livestock and more.

Our Pacific Modular brand traditional corrugated style tank is guaranteed* and has a number of features that set it apart from other steel tanks.

Our steel roof and walls are stronger and thicker than ordinary tanks.

We use special flanged tank bolts and nuts ensuring secure and easier construction.

Additionally included in our tank is a machined structural – steel roof edge for extra stability.

Altogether you get a tank that is very strong and an asset that will last.

Our tank package includes a Dome style roof, Leaf filter basket, “Vermin-Out”, Lockable Access Hatch, 50mm Outlet and Valve, and an Overflow with discharge pipe.

You have a choice of a “Potable” membrane (food contact grade for drinking water) or an “Ag” grade protective membrane (livestock, garden etc.), which protects your tank so it can’t rust, leak or crack like ordinary tanks.

A range of optional accessories are also available including: Ladders, Level Indicators, Extra outlets or overflows and larger outlets or overflows.

We can offer the traditional galvanized zinc or a range of Colorbond™ colours.

Your PACIFIC MODULAR TANK can be supplied in kit form for your easy installation, without foregoing all your warranty. Or an installed service can be arranged.

Biogas/Digester Systems

We understand that there is a greater demand for sustainable, renewable energy sources and digester systems for waste consumption to ensure a better environment. It is for this reason that we at Asia Pacific Tanks Pty Ltd (T/as PMT Water Engineering) are proud to be turnkey contractors of biogas and digestion plants including supply or consultation, design, equipment selection, installation, commissioning, training and support. Our bio-digestion systems and tanks for waste recycling and energy production utilise proven European engineering and bio technology including Semi Anaerobic Hydrolysis (SAH) technology which is taking the biogas industry to the next level in efficiency and reliability.

What Type of Substrates Can Our Systems Treat?

Our advanced Semi-anaerobic hydrolysis (SAH) systems treat a range of substrates, including even the most fibrous material such as cellulose rich feedstock. In addition they treat:

- Agricultural organic bio-waste: manure, pure corn straw, maize silage and grass silage

- Organic waste: kitchen waste, food waste, municipal organic waste and food industry byproducts

- Organic waste water with a high concentration of COD and BOD5

What Are The Benefits of Our Semi Anaerobic Hydrolysis (SAH) Systems?

One of the key benefits of the Semi anaerobic hydrolysis (SAH) technology compared to traditional anaerobic/bio-digestion processes is that it cuts down the hydraulic retention time (HRT) by more than half the traditional time. Additionally compared to traditional anaerobic /bio-digestion processes the semi-anaerobic hydrolysis (SAH) unit has:

- A high biogas yield for cellulose rich feedstock (straw, grass, husks, leaves, etc)

- A low hydraulic retention time of less than 25days

- Low energy consumption for agitation

- Easier pumping (no clogging)

- The possibility of heat recovery from the outflow of the digester

- Higher methane content

- Easier plant operation and higher plant stability thanks to the feeding of acetate

- The possibility of changing the feedstock quickly

What Are The Further Benefits of Our Biogas Systems?

- Produces methane gas or ethanol industrial alcohol for fuel

- Byproducts such as organic fertiliser

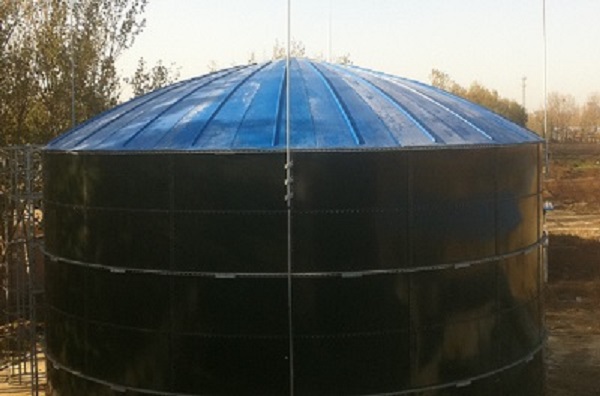

What Type of Tanks Are Used For Our Biogas Projects?

We use our quality factory coated range of Code AWWA D103.97 section 6 compliant Bonded Epoxy Tanks. Capacities up to 40ML with heights over 20m. Fusion bonded epoxy steel is highly resistant to aggressive contents such as raw sewage and industrial effluents with an extensive pH range of 2 to 13.

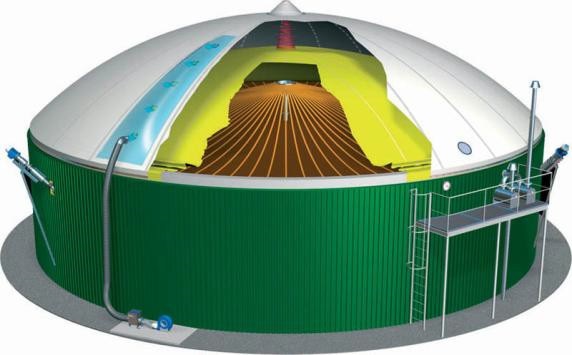

What Type of Roof Systems Are Utilised in Our Digesters?

We have a range of roof and cover systems that have a diverse set of functions that are fit for purpose:

- Glass Reinforced Plastic (GRP) Roofs:

– Material: Glass reinforced plastics

– Function: Odour control, rain-proof, snow-proof and dust-proof

Diameter <15m: no support

Diameter >15m: central column support & internal structural support

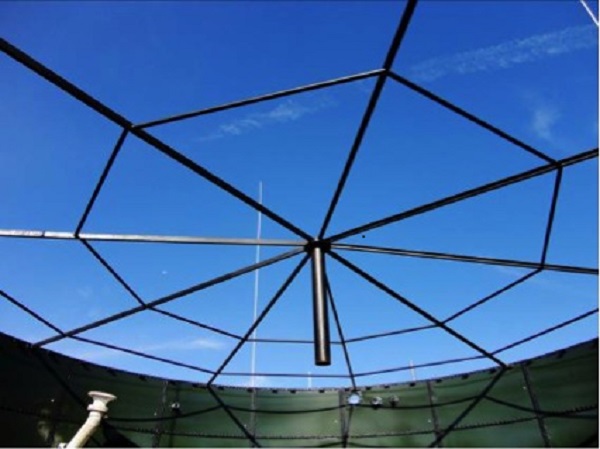

- External Beam Steel Digester Roofs:

– Material : Glass fused to steel or epoxy coated steel plates, bolted.

– Function: Gas and water tight properties , capable to be digester, waste water treatment reactor

- Single/Double Membrane Dome Roof Systems:

– Material: Double membrane roof systems have been developed and manufactured specifically for use with the biogas tanks systems. We utilise a proprietary membrane material that has been specifically treated to strengthen the polyester fibres. An acrylic resin varnish is used externally to create a robust roof system that is UV resistant.

– Function:

Single Membrane: odour control, rain, snow and dust protection

Double Membrane: biogas holder, gas and water tight

- External Gas Tank/Spherical Gas Holder:

– Material: Proprietary membrane material with special treatment to strengthen polyester fibres and an acrylic resin varnish

-Function: Gas-tight properties, H2S resistant, high UV resistance, odour control

Water Treatment

Packaged, both skid mounted or containerised systems and units ready for immediate pipe connection and service. Units for separation and filtration of raw and waste water and membrane-systems for potable and for “polishing water”, typically Reverse Osmosis and Desalination (RO) for clear , raw & brackish water or seawater.

Pre-treatment and filtration is mandatory for membrane performance, water output and lower maintenance. Pretreatment is typically for hardness but many trace elements are harmful to membranes .Some can be treated by continual dosing of commercially available chemical-products. Filtration is primary to separate out particulate , sand/ sediment and dirt. Chlorine is detrimental to RO and other membranes and this is ususally removed by chemical dosing or filtration , for example with Activated- Carbon filter media.

Filtration

Water Engineering offers solutions to a diverse range of challenges in water, liquids, gas and air. Utilising selections of cartridge or bag filter and filtration – media.

Ultra-Violet Sterilisation Equipment

UViFLO brand products were a leader in the Australian water disinfection market for over 14 years. This range is now superseded with the UV Guard brand UV range. Parts and service are still available for UViFLO equipment. We represent, sell with backup and also offer the manufacturers after sale service.

We can supply stock or custom built UV units for any requirement either domestic or industrial, drinking water or effluent.

What is UV Disinfection?

UV light is a particular selection of wavelengths from the light spectrum, occurring naturally in sunlight. It damages the DNA molecules in bacteria and viruses preventing them replicating and surviving to cause harm.

Germ killing (germicidal) UV light can be produced by a variety of lamps or arc tubes. The best suited are medium or low pressure mercury lamps. The reference to pressure relates to the gas in the lamp not the hydraulic operating rating of the system.

PMT Water Engineering recognises that for certain UV applications medium pressure UV lamps are optimal and for others, low pressure lamps.

We are unique in that we offer manufacture and supply a large number of both technologies for installations throughout the world.

- No micro-organisms are known to be resistant to UV. It is effective against bacteria, moulds, fungal spores, viruses and yeasts.

- The dose of radiation required to achieve a 90% kill or specific micro-organisms is called the D10 – the dose at which only 10% of the micro-organisms survive.

- Doubling the dose achieves an overall 99% reduction.

- Typical D10 figures are known for most micro-organisms.*

- UV systems are normally sized to achieve at least a 99.99% kill. Therefore a dose of four times the D10 is necessary.

- Taking E.Coli (D10 = 5.4mWs/cm2) as an example, the dose needed to achieve a 99.999% kill can be calculated as shown.

Some example of our Water Treatment Systems

Some example of our Tank Membranes and Replacement Liners

Tank Membranes and Replacement Liners

Liners: – Membrane’s of various polymers to suit many Dams, Water-courses and Tanks, designed in co-operation with our strategic vendor engineers, supplied and installed by us.

As policy we do not supply for plastic or so called “poly” tanks.

Large installations require onsite, in-field construction using specialist welding techniques.

We aim to have most membranes fully or partly cut and fabricated in the factory to reduce onsite work tasks, time and money. Whilst enhancing both QA and Quality Control.

Material of choice includes plastic polymers both solid and reinforced. Such as – PVC, Polyprophylene (PP) and Dupont (USA) brand “Evaloy” based compounds.

Membranes are selected and recommended to be compatible in a variety of applications and liquid contact. These include Potable Water, some Hydro-carbons and Fuels, also a range of Wastes, Chemicals and Acids. Temperature and or concentrations often determine ultimate compatibility or suitability.

Downloads

1-7.pdf

8-15.pdf

Aeon PTL–PTR.pdf

NB: Always seek professional advice and provide “full disclosure” to your prospective supplier.

Other Products

Water Treatment Plants

Modular ground, skid or ISO container mounted packaged systems ready for immediate pipe connection and service. We also offer civil-engineered in ground (in situ) plants and modular packages which can be backfilled and covered over. Usually up to 1500e.p. capacity and modules thereof.

Performance to International and Australian standards.

Filtration

pmt Water Engineering offers solutions to a diverse range of challenges in water, liquids, gas and air.

Dam Liners & Berms

Polymer liner membranes to suit dams, water courses and tanks designed and supplied / installed by pmt Water Engineering. We can also advise on bunds & berm lining. Materials of construction embraces plastic polymers such as P.V.C., Polypropylene, Butyl and ‘Evaloy’ based compounds. Membranes are available to be compatible with a wide variety of applications and chemicals including diesel, molasses (sugar by-products) and effluent wastes.

UViFLO brand products were a leader in the Australian water disinfection market for over 14 years. This range is now superseded with the UV Guard brand UV range. Parts and service are still available for UViFLO equipment. We represent, sell with backup and also offer the manufacturers after sale service.

We can supply stock or custom built UV units for any requirement either domestic or industrial, drinking water or effluent.